You might not think it, but technology plays a big part when it comes to cutting metal these days. Back in the ‘good old days’people would use something like an angle grinder to cut one piece of metal into two pieces. Nowadays, technology has opened up plenty of possibilities for the way metal cutting occurs.

We are no longer limited to cutting basic shapes and using creative welding techniques to finish the job. Thanks to technology, we can now have metal cut in all kinds of intricate and unique ways. Sometimes, we don’t even have to cut metal at all to fabricate a part (i.e. 3D printing).

So, if you have a need to cut some metal today, and you need to do it on a mass scale, how can technology help you out? Here are just a few examples of what’s available to you:

Drilling

A traditional way of cutting metal is to drill some holes, of course. Many years ago, this process would get done by hand using a standard drill or an industrial one on a bench. These days, it’s possible to get the work completed using technology.

All you have to do is offer up a sheet of metal on your bench, and you can a CNC machine to do the rest!

That way, you lower the risk of making a mistake because a computer does the calculations for you. Companies like Trade CNC claim that many clients want metal parts fabricated in this way as it saves them time and money. And it also means the risk of people injuring themselves is low.

Turning

Another way that technology can help you to cut metal is through a process known as turning. In a nutshell, a sharp tool gets applied to the surface of a metal object and is repeatedly spun. It makes it possible to remove the top layer of any metal so that your desired results can get achieved.

There are many applications where the turning process gets used. For instance, two metallic engine parts can get finished this way so that they form a ‘coupled’connection to each other.

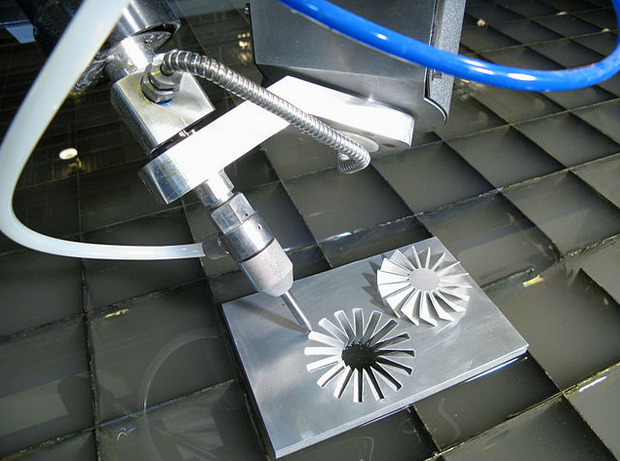

Water Jet Cutting

Let’s face it; most traditional forms of metal cutting require using something like metal or diamonds. But, did you know that it’s possible for metal to get cut with something that we all use each day? Yes, that’s right; I’m talking about water!

As you doubtless know, water and metal have long been arch enemies. If steel, for example, gets in constant contact with water, the metal will start to erode. Water jets speed up this process by applying a jet of H2O under pressure to a sheet of metal. The force is so strong that it will make a clean cut through the object in question.

The benefit of water jet cutting is that you don’t need to worry about replacing metal discs or diamonds on a regular basis. After all; you only need water, and we’ve got plenty of that available to us!

So, which method will you use for your next metal cutting project?